Production System

Manufacture conforms to GMP from raw material entry through to manufacture to quality assured product release.

Hamari is a manufacturer of intermediates and active pharmaceutical ingredients. We respond appropriately to changes of the times and individual needs. We endeavour to grow and meet our customers’ needs by promptly manufacturing high-quality products at low cost using an environmentally-friendly and GMP-compliant production system

Hamari has several different types of reactors to meet the various needs of our customers

- High-Pressure Reduction Reactor

- Capacity: 500 L SUS

Reactions under maximum of 6.8 MPa pressure

- Hastelloy Reduction Reactor

- Capacity: 500 L

High pressure reduction reactions under acidic conditions

- Thin-Film Centrifugal Low Pressure Evaporator

- Concentration of high-boiling solvents at low temperature

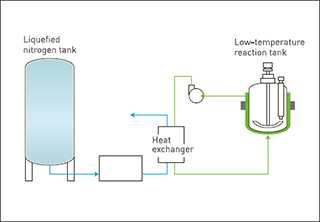

- Low Temperature Reactor

- Capacity: 500 L − 1700 L SUS

Cryogenic reactions at temperatures down to −90°C

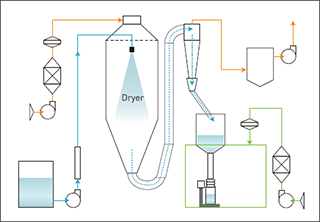

- Spray Dryer

- For drying heat-sensitive compounds

- Electrodialyzer

- For removal of inorganic salts in aqueous solution using an ion exchange membrane

- High-Potency Manufacture

- Synthesis of highly-potent compounds, Category 4 or Lower Download Brochure

- Kilo-Lab Facility

- 50 L GL vessel

- Solid-Phase Automated Peptide Synthesizer

- Scale: Maximum 50 mmol

- Clean Room

- Particulates ≤ 100,000/feet3

(Collection efficiency ≥ 0.5 μm, non-operational state)

Settling microbes ≤ 12 CFU/φ9cm.1h

Adhering microbes ≤ 50 CFU/10cm2

Differential pressure ≥ 1.3mm H2O